A wide range of nanocellulose particles, in term of morphologies and properties, can be obtained by playing on the preparations processes and the source of cellulose. From this diversity of cellulose nanoparticles, different solid structures can be prepared from various drying processes. The following sections deal with the production of nanocellulose 2D and 3D architectures, respectively.

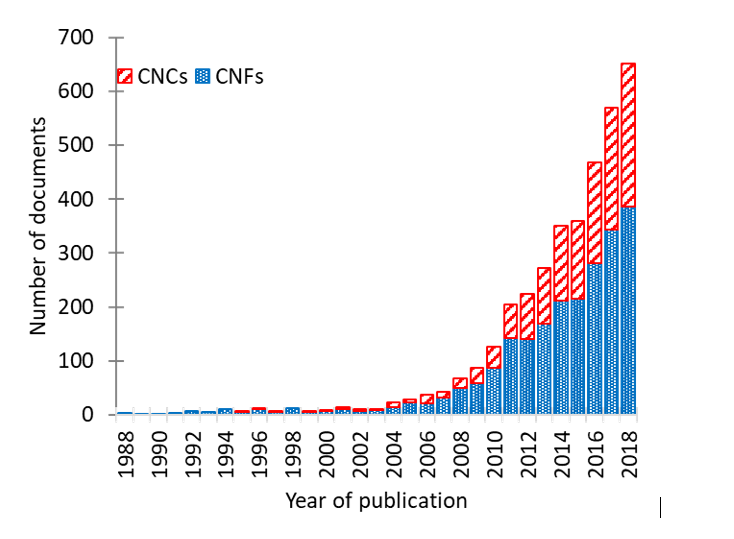

The number of documents related to nanocellulose surfaces (film, membrane or nanopaper) increased exponentially over the last two decades, with a higher amount of articles discussing cellulose nanofibril (2/3) surfaces over cellulose nanocrystal’s (1/3), as presented below.

Figure 6: Evolution of the number of documents (articles, conference papers, review and book chapter) on nanocellulose surfaces extracted from Scopus, July 2019 – descriptors for CNFs: cellulose nanofibril/cellulose microfibril / nanofibrillated cellulose/micro fibrillated cellulose, for CNCs: cellulose nanocrystal/cellulose whisker /cellulose nanowhisker / nanocrystalline cellulose and for 2D structures: film/nanopaper/membrane.

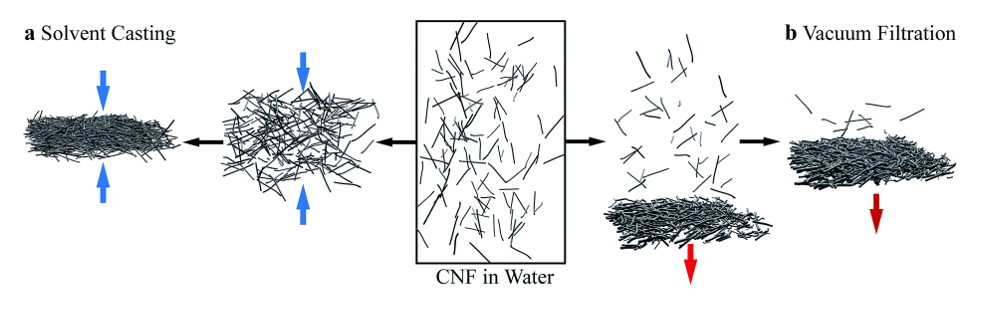

Hubbe et al. described different methods to prepare nanocellulose thin films: casting, filtration, coating and extrusion (Hubbe et al. 2017). The casting process used to produce films is generally performed from a suspension of nanocellulose in water. The solvent is removed through an evaporation process at room temperature or above (Spence et al. 2010; Fujisawa et al. 2011; Amin et al. 2012). During solvent casting, the water slowly evaporates, increasing the suspension concentration. The interactions between the particles (hydrogen bonding), induced by the capillary pressure, increase until aggregation. In the filtration process, also mentioned as the “papermaking process”, the nanocellulose are collected over a mesh or sieves, under vacuum solvent removal. A wet cake is obtained and subsequently dried under vacuum to avoid wrinkling. This process has been used to yield nanopapers of cellulose nanofibrils and nanocrystals (Tingaut et al. 2011; Sun et al. 2015; Cheng et al. 2017b).

Benítez and Walther described the different mechanisms involved in the production of films and nanopapers, namely solvent casting and vacuum filtration, respectively, which are illustrated in Figure 7 (Benítez and Walther 2017).

Figure 7: Schematic preparation of CNFs films by solvent casting (a) and CNFs nanopapers by vacuum filtration (b) (Benítez and Walther 2017)

The latter process yields nanopapers mechanical properties that depend on the water content, the porosity, the alignment of CNFs and the presence of counter-ions as reviewed by Benítez and Walther (2017). It has sometimes been stated that vacuum filtration also leads to higher orientation in the direction parallel to the filter membrane (Benítez and Walther 2017). Syverud and Stenius reported increased orientation for CNF nanopapers prepared with a sheet former (Syverud and Stenius (2008). The sheet former (Rapid-Köthen) used by Sehaqui et al. (2010a) led to increased orientation and was considered as the reason for increased mechanical properties. However, other studies reported the random in-plane orientation of cellulose nanofibrils in nanopapers of high toughness (Henriksson et al. 2008) or the necessity to cold-draw (stretch) the wet network to induce orientation.

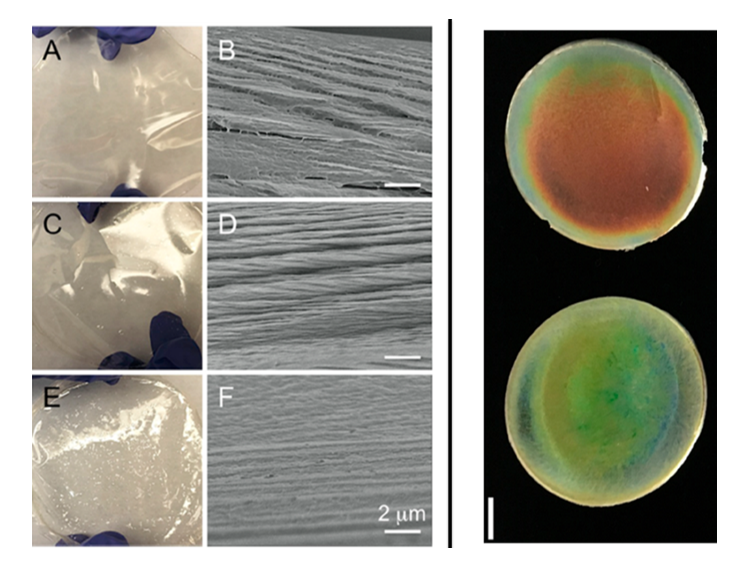

The drying temperature and time affect the morphology and properties of the resulting films. The effect of the drying temperature on the properties of TEMPO-oxidized CNF films has been investigated by Torstensen et al. (Torstensen et al. 2018). No defects were observed for films dried at ambient temperature, while an increasing amount of bubbles was observed in the film when the temperature increased. This behaviour is illustrated in Figure I.8 left. Overdrying also has an impact on the mechanical properties: films dried rapidly were more fragile. The impact of the drying time in CNC films resulted in a colour shift to the blue wavelength for CNC films dried over longer periods of time, as depicted in Figure I.8 right from Tran et al. (2018), with a red film obtained after 1-day drying and a green film obtained after an evaporation time of 10 days.

Figure 8: On the left: photographs and SEM images of TO-CNFs films dried at increasing temperatures from top to bottom: ambient, 35°C, 50°C. On the right: CNCs films dried over 1 day (top) and 10 days (bottom). From (Torstensen et al. 2018; Tran et al. 2018).

These 2D nanocellulose structures were investigated for a wide range of applications. Especially, barrier properties of nanocellulose films could be of great interest for the packaging industry (Fukuzumi et al. 2009, Syverud and Stenius 2008, Belbekhouche et al. 2011). Nanocelluloses were also used to prepare selective membranes for separation and sensors devices (Thielemans et al. 2009). The optical properties of the cellulose nanofibrils and nanocrystals films have been widely studied. Transparent CNF films production for electronic applications has been reviewed (Zhu et al. 2013). Cellulose nanocrystals iridescent films for photonics and optical materials were produced and the reflective properties tuned (Dumanli et al. 2014; Guidetti et al. 2016; Song et al. 2018; Tran et al. 2018). Applications in the energy storage field are also reported (Pérez-Madrigal et al. 2016).

In conclusion, two main processes are used to prepare 2D structures from different types of nanocellulose. The resulting materials exhibit different properties and are used for various applications. Because of the chiral nematic orientation of CNCs, films prepared from these particles have been widely studied for their optical properties. On the other hand, the excellent mechanical properties of CNFs have favoured the development of mechanical high-performance 2D structures.