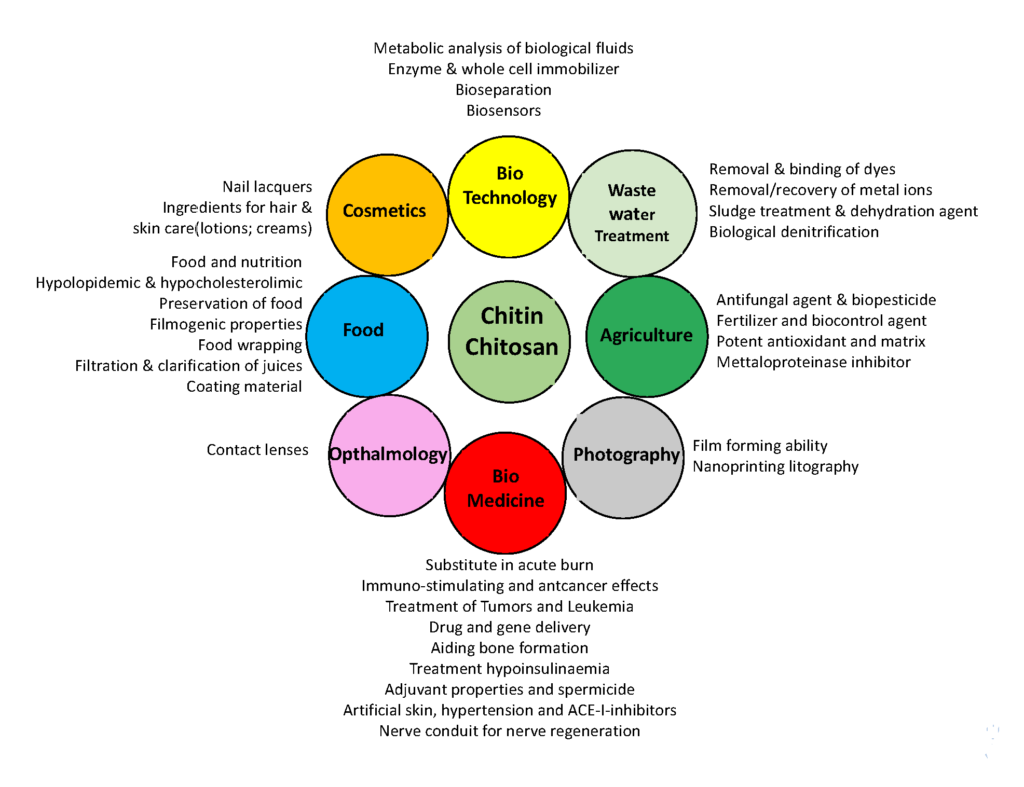

The high interest in medical applications of chitosan and some of its derivatives are readily recognized. The cationic character of chitosan is unique : it is the only pseudo-natural cationic polymer. Its film-forming properties and biological activity invite new applications.

12.1. Chitin-based Materials

Chitin has low toxicity and is inert in the gastrointestinal tract of mammals. It is biodegradable, owing to the presence of chitinases widely distributed in nature and present in bacteria, fungi, and plants as well as in the digestive systems of many animals. Chitinases are involved in host defense against bacterial invasion. Lysozymes from egg white, fig and papaya plants, degrade chitin and bacterial cell walls. A certain degree of deacetylation is required to allow the hydrolysis of chitin.Sashiva et al., 1990; Varum et al., 1997

Chitin has been used to prepare an affinity chromatography column to isolate lectins and determine their structures.Datta et al., 1984. Chitin and 6-O-carboxymethyl chitin activates peritoneal macrophages in vivo. They suppress the growth of tumor cells in mice and stimulate nonspecific host resistance against Escherichia coli infection. Chitin also accelerates wound healing.Hudson et al., 2003

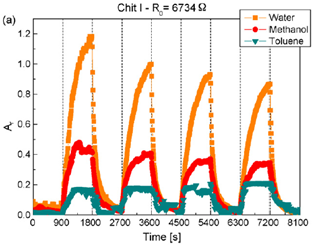

Chitin is widely used to immobilize enzymes and whole cells. Enzyme immobilization has applications in the food industry, such as clarification of fruit juices and processing of milk when α- and β-amylases or invertases are grafted onto chitin. Because of its biodegradability, nontoxicity, physiological inertness, antibacterial properties, hydrophilicity, gel-forming properties and affinity for proteins, chitin has found applications in many areas other than food such as in biosensors. One of these sensors was described for polar vapor detection.Bouvree et al., 2009

Chitin-based materials are also used for the treatment of industrial pollutants and adsorb silver thiosulfate complexesSongkroah et al., 2004and actinides.Songkroah et al., 2004 Chitin can be processed in the form of films and fibers.Austin et al., 1977; Hirano, 2001 The chitin fibers, obtained by wet spinning of chitin dissolved in a 14% NaOH solution, can also result in blending with cellulose Hirano, 2001; Hirano & Midorikawa, 1998 or silk.Hirano et al. 1990 They are non-allergic, deodorizing, antibacterial and moisture controlling.Yoshino et al.,1992 Regenerated chitin derivative fibers are used as binders in the papermaking process ; addition of 10% n-isobutyl chitin fiber improves the breaking strength of paper.Tokura et al., 1982; Kobayashi et al., 1982 However, the main development of chitin film and fiber is in medical and pharmaceutical applications as wound-dressing material. Yusof et al; 2003; Hudson 1998; 1999; Rathke et al., 1994 and controlled drug release.Kanke et al., 1989; Kato et al., 2003

Chitin is also used as an excipient and drug carrier in film, gel or powder form for applications involving mucoadhesive property. Another exciting application is in hydroxyapatite–chitin–chitosan composite bone-filling material. It forms a self-hardening paste for guided tissue regeneration in the treatment of periodontal bony defects.Ito et al., 1998 Chitin was O-acetylated to prepare gels which are still hydrolyzed by an enzyme such as hen egg-white lysozyme.Hirano et al., 1989; Zhang et al., 1994 CM-chitin was selectively modified to obtain anti-tumor drug conjugates.Ouchi et al., 1992 For example, 5-fluorouracil, which has marked antitumor activity and the D-glucose analog of muramyl-L-alanyl-isoglutamine, responsible for immuno-adjuvant activity were grafted on CM-chitin using a specific spacer and an ester bond.

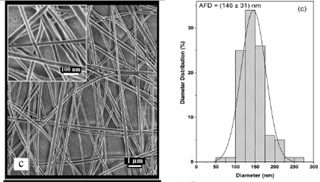

Chitin oligomers with DP = 5 is active in controlling the photo-synthesis of maize and soybeans.Khan et al., 2002 Considering the original properties of chitin especially for biomedical applications, the processes from solutions under different morphologies is interestingGarcia et al., 2018; Mengistu Lemma et al. 2018> Due to the low spinnability of chitosan alone, a water-soluble polymer PEO (MW 1×106 ) was blended with a chitosan solution in 0.5M acetic acid.

Such material after extraction of PEO, becomes a stable biomaterial over pH=7 with good mechanical properties and hydrophily (around 4g/g of dried material). It is well adapted for soft tissue engineering and wound healing. The advantage of the electrospinning technique is to obtain nanoscale fibers with high surface area to volume ratio.

Chitosan may be crosslinked by reagents such epichlorohydrin, diisocyanate Weish & Price, 2003 or 1, 4-butanediol diglycidyl ether.Roy et al., 1998 A blend of starch and chitosan can undergo specific crosslinking : starch was oxidized to produce a poly-aldehyde that reacts with the –NH2 group of chitosan in the presence of a reducing agent.Baran et al., 2004 Many chitosan hydrogels are obtained by treatment with multivalent anions : the case of glycerolphosphate is mentioned above Chenite et al., 2000, but oxalic acid has also been used as well as tripolyphosphate.Desai & Park, 2005; Lee et al., 1998Blends and composites have been prepared in the way mentioned previously for chi-tin.Wang et al., 2005> The advantage of chitosan in such materials is not only its biodegradability and its antibacterial activity, but also the hydrophilicity introduced by the addition of the polar groups able to form secondary interactions (–OH and –NH<sub>2</sub groups involved in H bonds with other polymers).

Chitosan-g-N-isAlbaopropylacrylamide (NIPAm) water-soluble copolymers were synthesized. They consist of LCST materials based on the properties of the poly NIPAm blocks. They display a thermoresponsive, fully reversible, behavior in aqueous solutions