11.1. Chitin Derivatives

Chitin displays properties such as biodegradability, and non-toxicity, which form the basis of many applications in bio-medicine, pharmacy, biotechnology, food industry, nanotechnology.Arguelles-Monal et al., 2018. Due to the analogy between cellulose and chitin, reactions are often performed in similar experimental conditions. For highly acetylated chitin, reactions allowing to generate chitin derivatives involve the hydroxyl groups at C-3 and C-6 positions in accessible zones. Considering data from the literature, it is necessary to precise that papers devoted to chitin derivatives are obtained in fact by chitosan modification (i.e chitin partially deacetylated). Then, due to their insolubility in many solvents (particularly chitin), chemical reactions are carried out under heterogeneous conditions. Using words from Kurita, “reactions under heterogeneous conditions are usually accompanied by problems including poor extents of reaction, difficulty in regioselective substitution, structurally ununiformly products, and partial degradation due to severe reaction conditions”.Kurita, 2006

11.1.1. Grafting on chitin. For grafting on chitin in most cases, radical polymerization has been used, although there is also a report of anionic ring-opening polymerization. Arguelles-Monal et al. 2018 Acrylic monomers (especially acrylic acid) are among the most frequently grafted into chitin. Therefore, almost no control over the macromolecular structure is attained, giving rise to a heterogeneous distribution of the grafting chains along the chitin backbone, and in some cases, only low degrees of grafting could be reached. Chitin-g-polypyrrole and chitin-g-polystyrene were obtained to increase the mechanical properties of initial chitin. Kurita et al investigate the influence of several conditions of the copolymerization reaction of acrylamide and acrylic acid onto chitin.Kurita et al., 1991 They were able to obtain percentages of grafting above 200 % with enhanced solubility and hygroscopic behavior.Kurita et al. 1991

11.1.2. Chitin modification. The most important derivative of chitin is chitosan, which is obtained by (partial) deacetylation of chitin in the solid-state under alkaline conditions (concentrated NaOH) or by enzymatic hydrolysis in the presence of a chitin deacetylase. Because of the semi-crystalline morphology of chitin, chitosans obtained by a solid-state reaction have a heterogeneous distribution of acetyl groups along the beta-chitin exhibits much higher reactivity for deacetylation than alpha-chitin.Kurita et al., 1993 The examination of the influence of this acetyl distribution.Aiba, 1991 show that the distribution, random or blockwise, is critical in controlling solution properties.

Reacetylation, up to 51%, of a highly deacetylated chitin in the presence of acetic anhydride gives a water-soluble derivative, whereas a heterogeneous product obtained by partial deacetylation of chitin is soluble only under acidic conditions, or even insoluble. NMR measurements have demonstrated that the distribution of acetyl groups must be random to achieve the higher water solubility around 50% acetylation. Homogeneous-ly deacetylated samples were obtained recently by alkaline treatment of chitin under dissolved conditions.Cho et al., 2000 On the other hand, the reacetylation of a highly deacetylated chitin was done Maghami & Roberts, et al., 1988 and provided homogeneous samples used in SEC analysis discussed previously.Brugnerotto et al. 2001 Toffey et al. transformed chitosan films cast from aqueous acetic acid into chitin by heat treatment.Toffey et al. 1996; Toffey & Glaser, 1999

After chitosan, the most studied derivative of chitin is carboxymethyl chitin (CM-chitin), a water-soluble anionic polymer. The carboxymethylation of chitin is performed similarly to that of cellulose ; chitin is treated with monochloroacetic acid in the presence of concentrated sodium hydroxide. The same method can be used for carboxymethylation of chitosan.Muzzarelli, 1985; Hudson & Jenkins, 2003; Muzzarelli, 1985 The method for cellulose derivatization is also used to prepare hydroxypropyl chitin, a water-soluble derivative used for artificial lachrymal drops.Wang et al., 1997; Park & Park, 2001 Other derivatives such as fluorinated chitin Chow & Khor, 2001, N and O-sulfated chitin Muzzarelli, 1985; Hudson & Jenkins, 2003; Muzzarelli, 1985; Tokura & Itoyama, 1994;Tokura et al., 1992, diethylaminoethyl chitin Kurita et al., 1990, phosphoryl chitin Andrew et al., 1998, mercapto chitin Yoshino et al., 1992 and chitin carbamates Vincendon, 1992 have been described in the literature. Modification of chitin is also often performed via water-soluble derivatives of chitin (mainly CM-chitin). The same type of chemical modifications (etherification and esterification) as for cellulose can be performed on the available C-6 and C-3 –OH groups of chitin.Rinaudo & Reguant, 2002 Chitin can be used in blends with natural or synthetic polymers ; it can be crosslinked by the same reactants as used for cellulose (epichlorohydrin, glutaraldehyde, etc.) or grafted in the presence of ceric saltRen et al., 1993 or after selective modification.Kurita & Inoue, 1989 The use of new solvents such as ionic liquids offer routes to further chemical modifications.

11.1.3. Depolymerization. Chitin is partially degraded by acid to obtain a series of oligochitins.Kurita et al., 1993 These oligomers, as well as those derived from chitosan, are recognized for their bioactivity : including anti-tumor, bactericidal and fungicidal activity, eliciting chitinase regulating plant growth. They are used in testing for lysozyme activity. They are also used as active starting blocks to be grafted on protein and lipids to obtain analogs of glycoproteins and glycolipids

11.2. Chitosan Derivatives

11.2.1. O- and N-Carboxymethylchitosans. Carboxymethyl-chitosan (CM-chitosan) is the most thoroughly explored derivative of chitosan ; it is an amphoteric polymer, whose solubility de-pends on pH. Controlled reaction conditions (with sodium monochloracetate in the presence of NaOH), yields O- and N-carboxymethylation. NMR establishes the yield of substituents on the three positions.Rinaudo et al., 1992 a; b; Le Dung et al., 1994 This reaction extends the range of pH (pH>7) in which chitosan is water-soluble, but a phase separation due to the balance between positive and negative charges on the polymer takes places in the range : 2.5<pH<6.5. Most impressive is the preparation of N-carboxymethyl chitosan by reaction with glyoxylic acid in the presence of a reducing agent.Le Dung et al., 1994 1H and 13C NMR established the distribution of monosubstituted (–NH–CH2COOH) and disubstituted (–N (–CH2COOH)2) groups. Disubstitution is easily obtained, giving a derivative for ion complexation. Specific oxidation of the C-6 position hydroxyl group was conducted using the TEMPO reactant on chitin to produce a chitin-based hyaluronic acid analog.Muzzarelli et al., 1999 This derivative is water-soluble in a wide range of pH, but only when prepared from fully acetylated chitin.

11.2.2. Chitosan 6-O Sulfate This derivative is an anticoagulant ; it was first prepared as an O- sulfated derivative Terbojevich et al., 1989)and as N-sulfated chitosan.Hoe & Perlin, 1997

11.2.3. N-methylene phosphonic chitosans. These anionic derivatives display some amphoteric character ; they were synthesized under various conditions and proved to have excellent complexing efficiency for cations such as Ca2+, and those of transition metals (Cu (II), Cd (II), Zn (II), etc.). Heras et al., 2000; Wojcik, 2003 The complexation provides protection against corrosion for metal surfaces.Wojcik, 2003These derivatives were also modified and grafted with alkyl chains to obtain amphiphilic properties that have potential applications in cosmetics.Ramos et al., 2003

11.2.4. Trimethyl chitosan ammonium. This cationic derivative is water-soluble over all the available pH range. It is obtained by quaternization of chitosan Domard et al., 1987 with methyl iodide in sodium hydroxide under controlled conditions. NMR provided its full characterization.Le Dung et al., 1994; Domard et al., 1987 Under all conditions tested, there appears a large decrease in molecular weight during this reaction. These polymers show good flocculating properties with kaolin dispersions, suggesting applications to papermaking.Domard et al., 1989 The other quaternized derivatives display antistatic proper-ties.Suzuki et al., 2000

11.2.5. Carbohydrate branched chitosans. Carbohydrates can be grafted on the chitosan backbone at the C-2 position by reductive alkylation. For that purpose, disaccharides (cellobiose, lactose, etc.) having a reducing end group, are introduced, in the presence of a reductant, on chitosan in the open-chain form.Hall & Yalpani, 1980These derivatives are water-soluble. A previous record mentioned galactosylated chitosan.Chung et al., 2002 Carbohydrates can also be introduced without ring opening on the C-6 position.Holme & Hall, 1992These derivatives are useful as they interact with the corresponding specific lectins and thus could be used for drug targeting.Morimoto et al., 2002 A particular case is the grafting of a cyclic oligosaccharide, cyclodextrin.

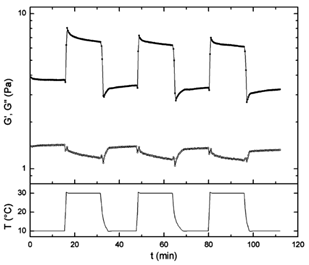

11.2.6. Chitosan-grafted copolymers. One of the most explored derivatives is poly(ethylene glycol)- grafted chitosan, which has the advantage of being water-soluble, depending on the degree of grafting. Higher molecular weight PEG at low DS give high-er solubility than low molecular weight PEG.Morimoto et al., 2002 PEG can be also be introduced by reductive amination of chitosan using PEG-aldehyde.Harris et al., 1984 Polypeptides have been grafted by reaction with N-carboxy anhydrides of amino acids to develop new biomaterials.Alba et al., 1986, but the degree of polymerization of the grafted chains cited in this work remains low (DP 5.9–6.6). Chitosan-g-N-isopropyl acrylamide (NIPAm) water-soluble copolymers were synthesized.Recillas et al., 2009. These polymers consist of LCST materials based on the properties of the poly NIPAm blocks. They display a fully reversible thermoresponsive behavior in aqueous solutions. The copolymers prepared were characterized by a LCST between 19 and 20 °C, when dissolved in 10% aqueous acetic acid.

11.2.7. Alkylated chitosans. Alkylated chitosans are very important as amphiphilic polymers based on polysaccharides. The first derivative having these characteristics was a C-10-alkyl glycoside branched chitosan with a high degree of substitution (DS) around 1.5, which gelled when heated over 50°C.Holme & Hall, 1991 Another approach was used for selective N- and O-palmitoylation giving a derivative with two or three long alkyl chains per monomeric unit. This reaction involved the protection and deprotection of the C-6 position.Kohgo et al., 1992Highly substituted derivatives with low regularity were prepared using carboxylic anhydrides with different chain lengths on CM-chitosan. They were insoluble in water and their biodegradability decreased.Hirano et al., 1992 Using the reductive amination, a series of amphiphilic derivatives were produced with different chain lengths (carbon chain from 3 to 14) and controlled DS (usually lower than 10% to maintain water solubility in acidic conditions).Desbrieres et al., 1996; Rinaudo et al., 2005

11.2.8. Cyclodextrin-linked chitosans. The cyclic oligosaccharides, namely α, β, γ -cyclodextrins (CD), are important because of their ability to encapsulate hydrophobic molecules in their toroidal hydrophobic cavity, whose selectivity depends on the number of glucose units (respectively 6, 7, 8 D-glucose units).Eli et al., 1999; Rekharsky & Inoue, 1998; Kriz et al., 2003 For various applications, it is interesting to graft the cyclodextrin on a polymeric backbone such as a biocompatible polysaccharide. A synthesis of α and β-cyclodextrin-chitosans with a relatively high degree of substitution has been described.Sakairi et al., 1999 The authors found that these new derivatives had the ability to differentially recognize and retain certain guest com-pounds based on their molecular shapes and structures. They proposed to use these polymers as supports for reverse-phase adsorption or as adsorbents in controlled release systems. A β-cyclodextrin with a specific modification on one of the –OH groups on its small side was grafted to chitosan by reductive amination. At a DS lower than 10%, these derivatives are water-soluble in acidic conditions with loose inter-chain interactions.Auzely & Rinaudo, 2003; Auzely & Rinaudo, 2001The grafted cyclodextrin has the same association constant Charlot et al., 2003