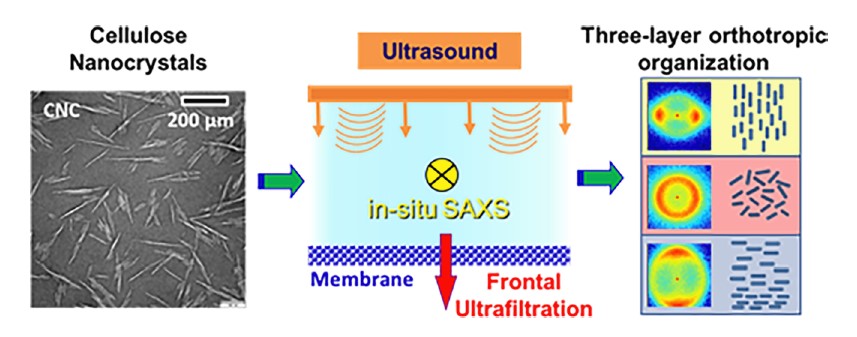

Cellulose nanocrystals (CNCs) are bio-sourced nanorods exhibiting a large variety of interesting intrinsic properties such as tunable aspect ratio and surface chemistry, exceptional mechanical properties, the ability to self-organize into liquid crystalline phases, non-toxicity, in addition to an abundant and renewable origin. Although CNCs have a high potential as elementary bricks in bio-sourced composites, achieving optimal performance of their functional properties remains difficult. One crucial aspect is the control of CNC orientation and organization over a broad spatial scale. The challenge is to achieve orthotropic organization in single-step processing, which entails creating non-uniform CNC orientations to generate spatial variations in anisotropy.

A novel processing method has been developed combining frontal ultrafiltration (FU) and ultrasound (US). A dedicated channel cell was designed to simultaneously generate (1) a vertical acoustic force thanks to a vibrating blade at the top and (2) a transmembrane pressure force at the bottom. Time-resolved in situ small-angle X-ray scattering permitted the probe of the dynamical structural organization/orientation of CNCs during the processing.

For the first time, a typical three-layer orthotropic structure that resembles the articular cartilage organization was achieved in one step during the FU/US process. The result comprises a first layer composed of CNCs having their director aligned parallel to the horizontal membrane surface, a second intermediate isotropic layer, and a third layer of CNCs with their director vertically oriented along the direction of US wave propagation direction.