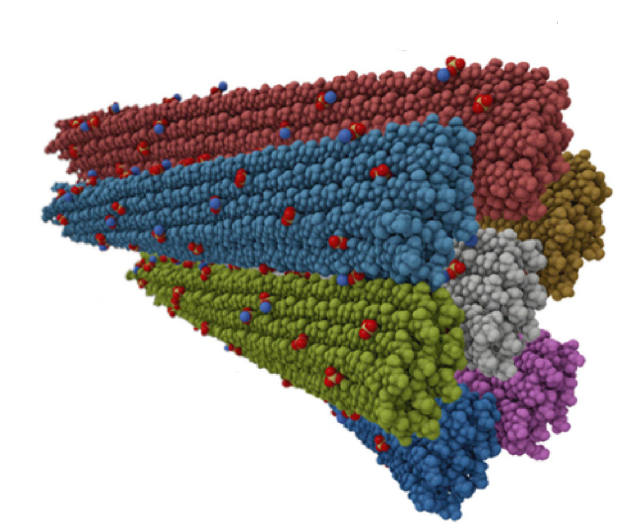

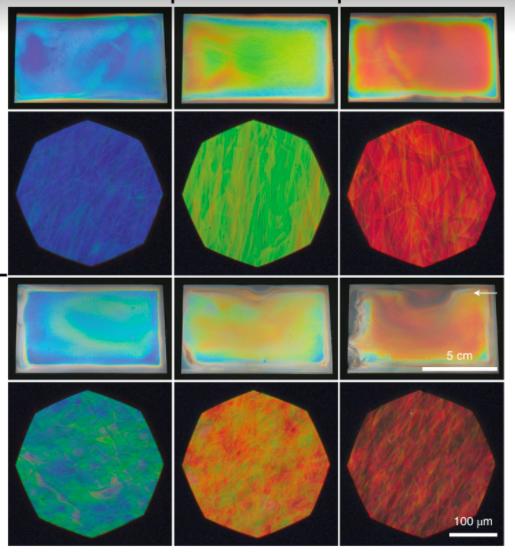

Cellulose nanocrystals are renewable plant-based colloidal particles capable of forming photonic films by solvent-evaporation-driven self-assembly. So far, the cellulose nanocrystal self-assembly process has been studied only at a small scale, neglecting the limitations and challenges posed by the continuous deposition processes required to exploit this sustainable material in an industrial context. Here, we addressed these limitations by using roll-to-roll deposition to produce large-area photonic films, which required optimization of the formulation of the cellulose nanocrystal suspension and the deposition and drying conditions. Metre-long structurally coloured films can be processed into effect pigments and dispersible glitters, even in water-based formulations. These bright effect pigments are an industrially relevant cellulose-based alternative to current products that are either micro-polluting (for example, non-biodegradable microplastic glitters) or based on carcinogenic, unsustainable or unethically sourced compounds (for example, titania or mica).

The authors expect the industrial relevance of this process will spark interest in the commercial development of eco-friendly photonic pigments. They could replace non-biodegradable microplastic glitters and unsustainable or unethically produced inorganic effect pigments in paints, inks, cosmetics, beverages, labelling and packaging.