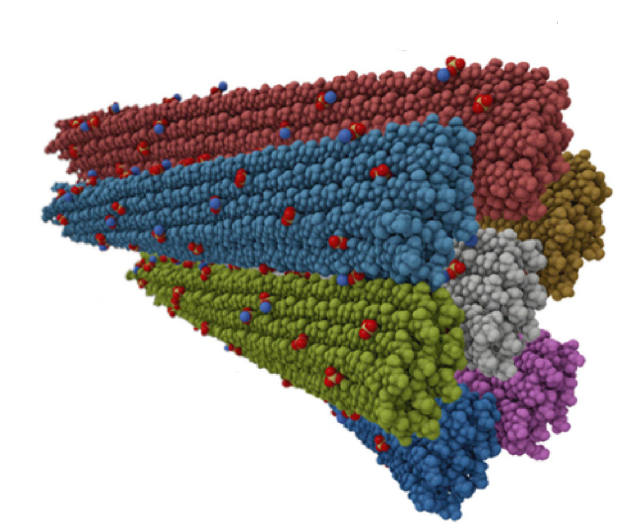

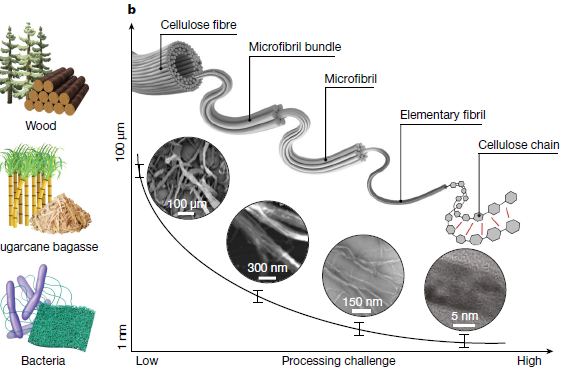

Cellulose is the most abundant biopolymer on Earth, found in trees, waste from crops and other biomass. The fibres that comprise cellulose can be broken down into building blocks, known as fibrillated cellulose, of varying, controllable dimensions that extend to the nanoscale.

Fibrillated cellulose is harvested from renewable resources, so its sustainability potential combined with its other functional properties (mechanical, optical, thermal and fluidic, for example) gives this nanomaterial unique technological appeal. The authors explore the use of fibrillated cellulose in the fabrication of materials ranging from composites and macrofibres to thin films, porous membranes and gels. They discuss research directions for the practical exploitation of these structures and the remaining challenges to overcome before fibrillated cellulose materials can reach their full potential. Finally, they highlight some key issues towards the successful manufacturing scale-up of this family of materials.